Name:BR0.8 plate heat exchanger

Technical parameters:

Model Model BR0.8

Monolithic effective area Active Per Plate Area 0.81m2,

Plate corrugation depth Nominal gap 4 0mm

Plate thickness Thi ckne SS 0.6mm

Plate corner hole size Port dim 200mm

Max flow Max flow 408M3 / H rate

Nozzle diameter Connection diameter DN200

Working pressure Working 0.6MPa, 1.0MPa, 1.6MPa, pressure

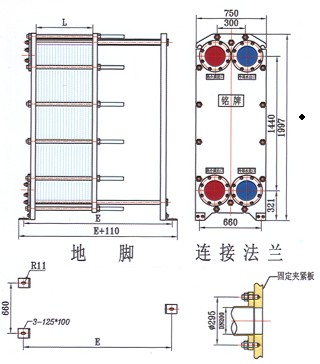

Two, the overall size of the equipment:

Type heat exchange area plate number I F weight flow

Type area (M2) number plates weight (Kg) Flow rate (m3 / H) (of)

BR0.8--A 658137413001773132

BR0.8--C 200251115521001866 408

The A is the smallest assembly area, C is the largest assembly area.

The size of L (mm):L= compression (4.6 + 0.2) x number of plate

The water flow is according to the single board process, ask the flow rate of 0.4m / S Computing

We reserve the right to change the above data, the data for reference only, the specific kind prevail

Three, plate heat exchanger

Plate heat exchanger is composed of frame, heat transfer plate and clamping bolts.

The frame comprises a fixed pressing plate and a movable pressing plate, which is supported by an upper guide rod and a lower guide rod. The corrugated plate is pressed on the upper guide rod between the two plates, and the movable pressing plate is pressed by the movable pressing plate, and a fixed clamping plate and a movable clamping plate are clamped to a certain size by a group of clamping studs. Two kinds of media are fixed (or active) on the flange of the plate into the hole by the corrugated plate of the respective channels, the heat exchange medium and then by the fixed (or active) on the flange hole. The fixed pressing plate, the movable clamping plate, the supporting rod and the guide rod are all low carbon steels. Taking into account a variety of user requirements, the design of the framework of a variety of types, mainly double support frame and commonly used floor type, etc., can also be based on user requirements to change the type of framework.

Heat transfer plate is one of the core components of plate heat exchanger. The corrugated plate is formed by pressing once, and the effective heat transfer area of the plate is increased by the reasonable design of the corrugated plate. When the assembly of corrugated and corrugated into a large number of contact points, greatly improving the stiffness of the plate group, so it can withstand high pressure. Each plate is used as a heat transfer surface, and both sides of the plate are respectively provided with a hot and cold medium through the action of the sealing pad. There are four liquid distribution alone L plate, L plate and hole installed around the gasket, limiting medium flow in the plate group, each sheet forming parallel channels, two medium flows through the inside of the best effect of heat transfer in the direction of flow, to adapt to a variety of corrosive medium, corrugated plate material: pure titanium TAl used in seawater or other corrosive medium; a variety of stainless steel, with j= water, drinking water, oil and other non corrosive media.

The utility model is characterized in that a sealing gasket is arranged on the sealing groove of the corrugated plate, and a sealing gasket is designed with a double channel sealing structure. When the medium such as from the first seal leakage, can be discharged from the signal equipment alone L, it can be found as soon as possible to solve the problem, will not cause the mixing of two media. Different types of rubber can be selected according to different fluid and operating temperature.

Four, plate heat exchanger plate material:

* stainless steel SUS304 SUS316L

Water, Kawa Kawazu, food oil, mineral oil

* industrial pure titanium and titanium palladium alloy Ti Tanium and Pal ladium

Sea water, brine, salt

* Hastelloy alloy Hadtelloy Alloy

Concentrated sulfuric acid, hydrochloric acid, phosphoric acid

* nickel Nickel

High temperature and high concentration of caustic soda

Five, plate heat exchanger gasket material:

* nitrile rubber NBR

Water, sea water, mineral oil, salt water 15--1IO~C

* high temperature rubber BNBR -

High temperature mineral oil, high temperature water 15--140~C

* three EPDM

Hot water, steam, acid and alkali 25--150~C

* fluoro rubber Viton / Fluorine Rubber

Strong acid, strong alkali, mineral oil, grease and oil, etc. 5--180~C

* chloroprene rubber NEOPRENE

Acid, alkali, mineral oil, low molecular weight hydrocarbon 35--130~C

* silicone rubber Silicon Rubber

High temperature and corrosive medium 65-200

Six, plate heat exchanger design concept:

* new diversion area design plate with increasing pressure is used in place of multi-channel plate flow diversion area increased pressure, make the whole piece of the plate in the velocity is equal, greatly improving the efficiency of heat exchange plate, reduces the dead, improve the fouling status of plate.

The design of the high strength hanging mouth of the plate is to increase the design of the pattern at the opening of the mouth, to strengthen the rigidity around the flanging, and to assemble the utility model more orderly and beautiful.

* groove design plate the middle part of the foot plate continuous corrugated plate inside the broken plate, coexistence of I}l increased the half groove structure, ease the pressure on the plate, the plate forming after the whole, Bu Yi, bending.

The interlocking design of the plate is a special mechanical interlock structure which is pressed at the four corners of the plate, which can improve the phenomenon of easy to be leaked in the process of the plate assembly, which makes the assembly of the plate more convenient and beautiful.

The plate gasket is all made of non sticking hasp, which can reduce the cost of operation and maintenance.

Seven, the technical advantages and characteristics of plate heat exchanger:

* high heat transfer coefficient: special design of corrugated plate heat transfer plate, the fluid to generate strong turbulence at low flow velocity, the turbulent effect of self purification and can prevent the occurrence of fouling, 3-5 times of the heat transfer coefficients of plate heat exchanger heat exchanger shell and tube.

* Economy: under the premise of the same heat exchange, compared with the shell and tube type: less investment, low operating costs, low maintenance costs.

* adjustability: simply increase and reduce the plate to meet the changing needs of the process.

* compact structure: under the premise of the same heat exchange, the occupied space is only 1 / 2 L / 1 of the shell and tube type

* easy cleaning and maintenance

Eight, plate heat exchanger design selection:

(1) physical parameters of cold and hot medium, such as pH, chloride content, viscosity, density, thermal conductivity, specific heat and so on.

(2) inlet and outlet temperature of cold and hot medium.

(3) the flow rate of a cold or hot medium or the flow of one.

(4) pressure loss of cold and hot medium.

(5) the inherent characteristics of plate heat exchanger, such as sheet material, sealing material, etc..