Plate heat exchanger

The utility model is a novel high-efficiency heat exchanger which is composed of a series of metal sheets with a certain corrugated shape. A thin rectangular channel is formed between various plates, and heat exchange is performed through a half sheet. Compared with the conventional shell and tube heat exchanger, the heat transfer coefficient is higher in the same flow resistance and pump power consumption. The plate heat exchanger is a heat exchanger which is formed by pressing a thin metal plate into a heat exchange plate with a certain corrugated shape, and then stacked with a clamping plate and a bolt. The flow of a fluid through a narrow, tortuous passage between two plates. The hot and cold fluid passes through the flow passage in sequence, and the middle part is provided with a partition plate to separate the fluid and heat transfer through the plate. The structure and heat transfer principle of plate heat exchanger has the characteristics of compact structure, small occupation area, high heat transfer efficiency, large operating flexibility, wide application range, small heat loss, convenient installation and cleaning, etc.. The average temperature of two kinds of medium can be as small as 1 DEG C, the heat recovery efficiency can reach more than 99%. In the case of the same pressure loss, heat transfer plate heat exchanger is a tubular heat exchanger 3 ~ 5 times, covers an area of the 1/3, only the consumption of metal 2/3. The plate heat exchanger is a kind of advanced heat exchange equipment with high efficiency, energy saving, material saving and investment saving.

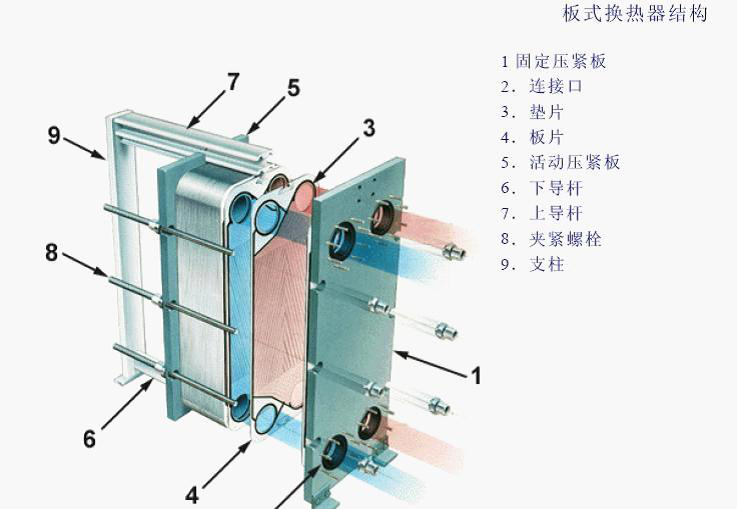

Plate heat exchanger is mainly composed of two parts: frame and plate.

The sheet made of various materials is pressed into various shapes with different forms of abrasive tools, and an angle hole is arranged on the four corners of the plate. The periphery of the plate and the hole are sealed with a rubber gasket.

The frame is composed of a fixed clamping plate, a movable clamping plate, an upper and a lower guide rods and a clamping bolt.

Plate heat exchanger is a plate in the form of superimposed on the fixed compression plate, the middle of the dynamic compaction plate, and then clamp with a clamping bolt.

The components are as follows:

Heat transfer plate

Heat transfer plate heat exchanger is the main role of heat transfer components, the general corrugated to do adult shaped, in accordance with the fluid medium, heat transfer plate material is not the same, mostly made of stainless steel and titanium.

Two, sealing gasket

The sealing gasket of plate heat exchanger is mainly used to seal the heat exchange plate. Material: nitrile rubber, three ethylene propylene rubber, fluorine rubber, etc., according to different media using different rubber.

Three, both ends of the pressure plate

Both ends of the clamping plate is clamped to suppress all the heat transfer plates to ensure that the fluid medium does not leak.

Four, clamping bolt

The clamping bolt is mainly used for fastening the two ends of the pressure plate. The clamping bolt is usually a double thread, and the moment of the fixing plate is even when the bolt is tightened.

Five, rack

The utility model is mainly supported by a heat exchanging plate, which is convenient for disassembly, cleaning and assembly.

Reed heat exchanger (Jiangyin) Co. Ltd is a UK based global famous heat exchanger manufacturers and maintenance business ARD PHE LIMITED's wholly-owned subsidiary, is specializing in the production of detachable heat exchanger (PHE) gasket, heat exchanger (PHE GASKET), plate heat exchanger (PHE PLATE) and provide maintenance services the plate heat exchanger (PHE MAINTENANCE) professional heat exchanger manufacturers. Reed (ARD) in the world with a number of standard chemical plant and stock center, service and sales outlets all over the world.

With the design and production of the world's most advanced technology and the most comprehensive heat exchanger professional knowledge, ARD has been committed to the global more than and 50 countries and regions of the petroleum, chemical, industrial, food and beverage, electric power, metallurgy, shipbuilding, HVAC industry customers for the high quality heat exchanger, the heat exchanger for more than 50000 of the good operation in various industries, ARD has become a global leader in the field of detachable heat exchanger.

At the same time is the plate heat exchanger accessories (heat exchanger plate and heat exchanger gasket) in the field of the world's number one supplier and maintenance. To provide the world famous brands (including: /AlfaLaval, /SPX, Alfa Laval s.b.c. amp /APV, /GEA, GEA Wei te /TRANTER, /SWEP, /SONDEX, Saunders shuruipu April. /API.Schmidt Schmidt, Japan Osaka /HISAKA, Funke /FUNKE, nisos Weifu / Thermowave, Vicarb, and /DONGHWA Entai vicarb East, ACCESSEN, MULLER, Exxon FISCHER, REHEAT, etc.) of plate heat exchanger gasket and all types of. About 1/5 of the world's plate heat exchanger is using ARD to provide heat exchanger parts or accept ARD maintenance services (including regular cleaning, maintenance and replacement parts, such as maintenance services).

No matter where you are, no matter what you have special requirements, ARD can provide you with the field of plate heat exchanger system solutions.