Technology for determining the flow combination of detachable plate heat exchanger

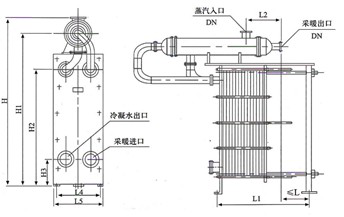

Plate heat exchanger is composed of many stamping corrugated plates at certain intervals, all around through the gasket seal, and pressing frame and overlapping spiral pressed plate and a gasket, the angle of the four hole forming fluid distributing and collecting pipe, and reasonably cold and hot fluid separately, which were flowing in on both sides of each runner plate, through the heat exchange plate.

Because of the special role of plate heat exchanger with corrugated surface, change the size of the fluid direction along the narrow curved channel flow velocity constant, resulting in less fluid flow velocity, aroused strong turbulence, thus accelerating the fluid boundary layer destruction, to strengthen the heat transfer process, can effectively improve the heat transfer capacity. Which has the advantages of compact structure, low metal consumption, operation flexibility, small heat loss, installation, inspection and convenient, strong corrosion resistance, long service life and other advantages. Each plate of AI Reed has at least two plates, and the heat transfer and pressure drop of the heat exchanger can be integrated by using the technology of thermal mixing. The inner bypass, the double channel technology and the unequal flow cross section assembly provide the perfect solution for the two sides of the medium flow rate difference. ARD plate heat exchanger has AB series, AM series, AL series, AP series, AS series, such as several large series of more than one hundred kinds of plates. Various models have deep ripple, shallow ripple, large angle, small angle, fully meet the needs of different users, special conditions can be designed and manufactured according to user needs.

A group of parallel flow heat exchanger in the process of the fingerboard of a medium with a flow direction, flow and fingerboard heat exchanger, two adjacent plates composed of medium flow channel. In general, a plurality of flow channels are connected in parallel or in series to form a combination of cold and hot media channels.

Plate heat exchanger is the process of many pieces of sheet according to a certain process and the requirements of the technical requirements of the assembly. The utility model is characterized in that four corner holes are formed between the plates to form a distribution pipe and a confluence pipe, and the sealing pad is used for sealing the hot and cold medium in the heat exchanger. In the cold and hot fluid flow inside the channel, can also flow downstream, in the flow process of hot and cold fluid through the heat exchange plate. Plate type heat exchanger, many processes are combined, using different reversing plates and different assembly process to achieve the combination of the form can be divided into single process and multi process and gas-liquid exchange process, mixed flow form.

The form of flow combination should be determined according to the heat transfer and fluid resistance. As far as possible, the convection heat transfer coefficient in the cold and hot water channel is equal or close, so as to get the best heat transfer effect. Because the convective heat transfer coefficient is equal or close to the heat transfer surface, the heat transfer coefficient is obtained. Although the plate plate flow velocity varies, but in the calculation of heat transfer and fluid resistance, the average flow rate is calculated. Due to the "U" shape of the single process of the tube are fixed on the board, easy disassembly.