Name:longteng Transferand exchanger pharmaceutical industry solutions

Biotechnology and pharmacy

There are many kinds of heat exchangers, which can be divided into tube type, plate type and other types of heat exchanger according to the shape and structure of heat transfer surface. The tube type heat exchanger can be divided into the heat exchanger, tube shell type casing heat exchanger, tube heat exchanger; plate type heat exchanger can be divided into the heat exchanger, plate fin heat exchanger, plate heat exchanger, spiral plate heat exchanger. Other types of heat exchangers are to meet the special requirements of the heat exchanger, such as rotary heat exchanger, heat pipe heat exchanger, etc.. The shell and tube heat exchanger can be divided into condenser, heater, reboiler, evaporator, superheater and so on. Here are some of the commonly used several heat exchangers.

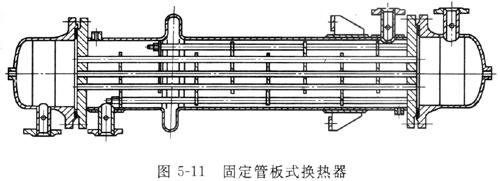

1 fixed tube plate heat exchanger

Fixed tube plate heat exchanger at both ends of the tube plate, the welding method and the shell is connected to the fixed, as shown in figure 5-11. The heat exchanger has the advantages of simple structure, and the row tube is the most compact in the same shell diameter. The two tube plate heat exchanger was compared with other support each other to grab, shell and tube heat exchanger tube plate, the thin, not only low cost and inside of each pipe for cleaning. However, it is difficult to clean the shell side and can not be cleaned mechanically, so it is suitable for the fluid which is not easy to scale. When the temperature difference between the tube bundle and the shell is too large to produce different thermal expansion, the interface between the tube and the tube plate can be separated, and the dielectric leakage occurs. It can be seen that the heat exchanger is suitable for occasions with low temperature difference and no serious fouling in the shell side or chemical cleaning. Because of the advantages of the shell and tube heat exchanger, the heat exchanger is widely used.

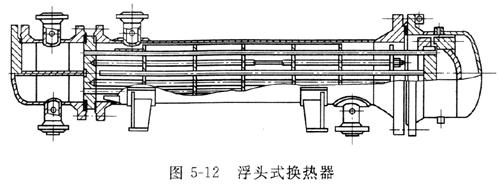

2 heat exchangers

Floating head heat exchanger as shown in figure 5-12. The defects of floating head heat exchanger for a fixed tube heat exchanger is improved in structure, both ends of the tube plate and the casing is fixed at one end, and the other end of the tube plate can move freely within the housing, the end is called a floating head. This kind of heat exchanger shell and tube bundle is free to thermal expansion, so when two kinds of medium temperature difference is big, the tube bundle and shell does not produce temperature stress. Floating head removable side structure is designed, so that the control can be easily inserted or extracted (also designed not detachable), such as maintenance and cleaning more convenient.

Floating head heat exchanger for shell and tube wall temperature difference, or easy to corrosion and easy scaling. But this kind of complicated structure of the heat exchangers, heavy, high cost about than the fixed tube plate 20%, material consumption.

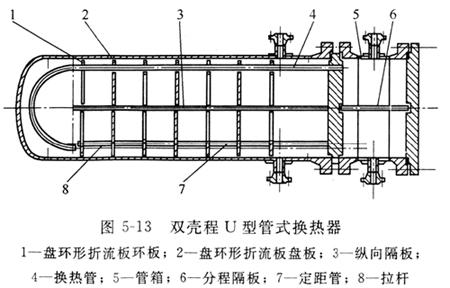

3 U tube heat exchanger

U type tube heat exchanger as shown in Figure 5-13, U type tube heat exchanger has only one tube plate. The utility model is characterized in that the pipe is bent into a U shape, and both ends of the pipe are fixed on the same tube plate. Due to the separation of the shell and the tube, the tube bundle can be freely telescopic, and the thermal stress can not be generated due to the temperature difference between the pipe wall and the shell wall. The tube is double pipe, the flow is long, the flow rate is high, the heat transfer performance is good, the pressure bearing ability is strong. For U type heat exchanger with a tube plate and the floating head, so the structure is simple, the cost is cheaper than other heat exchanger tubes can be extracted from the shell and tube is convenient to clean, but tube cleaning is difficult, so the fluid in the tube must be clean and not easy to scale material.

U type tube heat exchanger, generally used in the case of high temperature and pressure. Especially in the case of high pressure, the elbow section of wall thickness to thicken, to make up for the elbow pipe wall thinning.

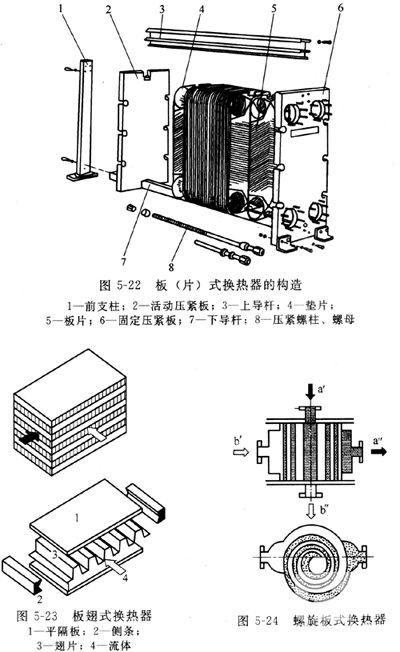

4 plate heat exchanger includes plate, plate fin and spiral plate three structures, the most widely used is the plate type heat exchanger, usually referred to as plate heat exchanger.

If it is to plate heat exchanger as a partition, said heat exchanger plate type, as shown in figure 5-22. In the heat exchanger, the fluid flow along the plate heat transfer coefficient is small, usually on the plate and fin plate or try to make fluid in spiral motion to enhance heat transfer, so that the heat exchanger composed of said heat exchanger fin (Fig. 5-23) and spiral plate heat exchanger (Figure 5-24). There are some heat exchanger partitions are pressed into corrugated shape, also can enhance heat transfer.

Plate type heat exchanger has the advantages of high heat transfer coefficient, small occupied area, to achieve a variety of heat transfer medium, the logarithmic mean temperature difference is small, the terminal temperature difference is small and easy to use, but can withstand the working pressure is low (usually less than 2.5MPa), cannot be used for fluid containing larger solid particles.